For more details about Major Component Exchanges, feel free to reach out to JMS Energy through jmsenergy.net.

What is Major Component Exchanges (MCE)?

Major Component Exchanges (MCE) is the process of replacing large, critical parts in renewable energy systems, primarily in wind turbines. These major components include gearboxes, generators, blades, main bearings, and transformers. MCE helps maintain the efficiency and operational integrity of the energy system by replacing worn or failed parts.

Why is Major Component Exchanges necessary?

MCE is necessary to prevent significant downtime, prolong asset life, improve cost-effectiveness, and enhance system performance. It allows energy companies to quickly replace faulty parts, ensuring minimal disruption to energy production and maximizing the operational lifespan of equipment.

What components are typically replaced during a Major Component Exchange?

During an MCE, large and critical components such as gearboxes, generators, blades, main bearings, and transformers are typically replaced. These parts are crucial to the functioning of a renewable energy system, and their failure can lead to significant downtime and performance issues.

How do Major Component Exchanges differ from regular maintenance?

Regular maintenance involves routine inspections, minor repairs, and servicing to keep systems running smoothly. Major Component Exchanges, on the other hand, focuses on replacing large and critical components that have reached the end of their operational life or have failed. MCE is a more extensive and specialized process compared to routine maintenance.

How is the need for a Major Component Exchange determined?

The need for an MCE is typically identified through condition monitoring systems (CMS). These systems continuously monitor the health of critical components by analyzing data like vibrations, temperature variations, and operational stress. When CMS detects significant wear or failure risks, it triggers the planning of an MCE.

What are the steps involved in a Major Component Exchanges?

The steps involved in an MCE typically include:

Condition Monitoring: Analyzing the health of components.

Logistics and Planning: Coordinating the transportation and storage of new components.

Replacement: Dismantling the faulty part and installing a new one.

Testing and Commissioning: Ensuring the new component functions correctly.

Post-Exchange Monitoring: Continuously monitoring the new component for performance.

How long do Major Component Exchanges take?

The duration of an MCE depends on the size of the component and the complexity of the exchange. It can take anywhere from several hours to a few days, depending on the logistics, tools, and equipment involved in the exchange process.

What are the benefits of performing a Major Component Exchange?

Performing an MCE helps in minimizing downtime, extending asset life, improving system performance, and reducing the overall cost of repairs. It allows energy companies to proactively address potential issues before they lead to larger failures, ensuring continuous and efficient energy production.

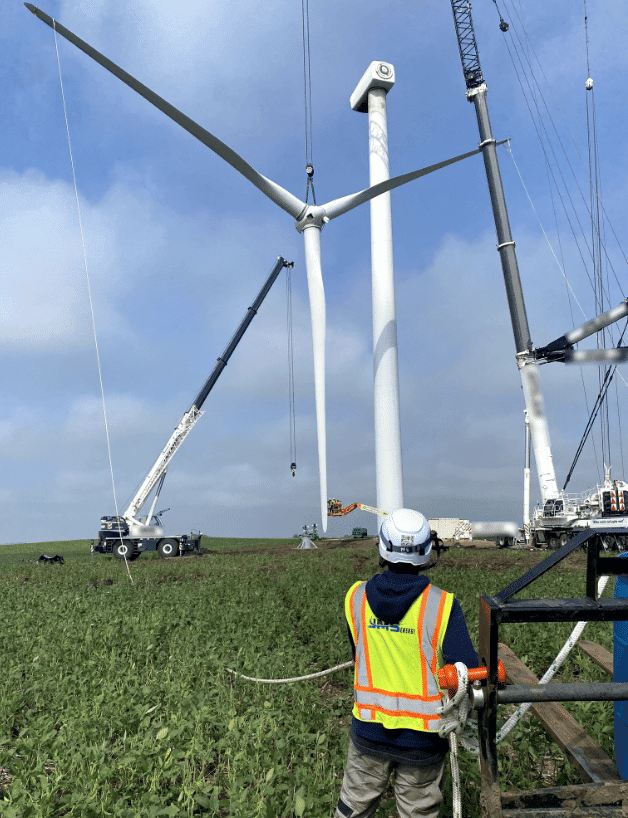

How does JMS Energy handle Major Component Exchanges?

JMS Energy offers turnkey MCE services, handling everything from condition monitoring and logistics to the safe replacement and post-exchange monitoring of components. With comprehensive expertise, state-of-the-art equipment, and a focus on safety, JMS Energy ensures that each MCE is completed efficiently and effectively.

Is Major Component Exchange only for wind turbines?

While MCE is primarily associated with wind turbines, the concept can be applied to other renewable energy systems that have large, critical components. The approach may vary depending on the type of energy system, but the principle of replacing key components to maintain efficiency remains the same.