Table of Contents

In today’s energy landscape, the demand for sustainable, renewable energy solutions continues to grow, and EPC (Engineering, Procurement, and Construction) companies play a vital role in meeting these needs. JMS Energy has emerged as a pioneering renewable energy EPC company, with over 30 years of experience providing top-tier services in wind, solar, battery storage, and fiber optics projects across the United States. With a strong commitment to safety, quality, and on-time project delivery, JMS Energy consistently brings expertise and innovation to the renewable energy industry.

What Sets JMS Energy Apart as a Renewable Energy EPC Company?

As a full-service renewable energy EPC company, JMS Energy offers a comprehensive approach to renewable projects, managing every phase from initial design and planning through construction and final commissioning. This end-to-end model ensures seamless integration of systems, streamlined communication, and reduced project timelines, ultimately leading to cost savings and increased efficiency for clients.

Key Attributes of JMS Energy as a Renewable Energy EPC Company:

- Experienced Team: JMS Energy has one of the most experienced teams in the industry, with over 230 completed projects across 32 states. Their extensive background in renewable energy ensures that each project is executed with precision.

- Commitment to Safety: Safety is a core value at JMS Energy, with industry-leading practices that help them maintain an impressive safety record. The company’s Total Recordable Incident Rate (TRIR) of 0.00 is a testament to their rigorous safety standards.

- Innovative Solutions: JMS Energy’s solutions-oriented approach allows them to foresee challenges and adapt quickly, delivering projects that meet both current needs and future energy demands.

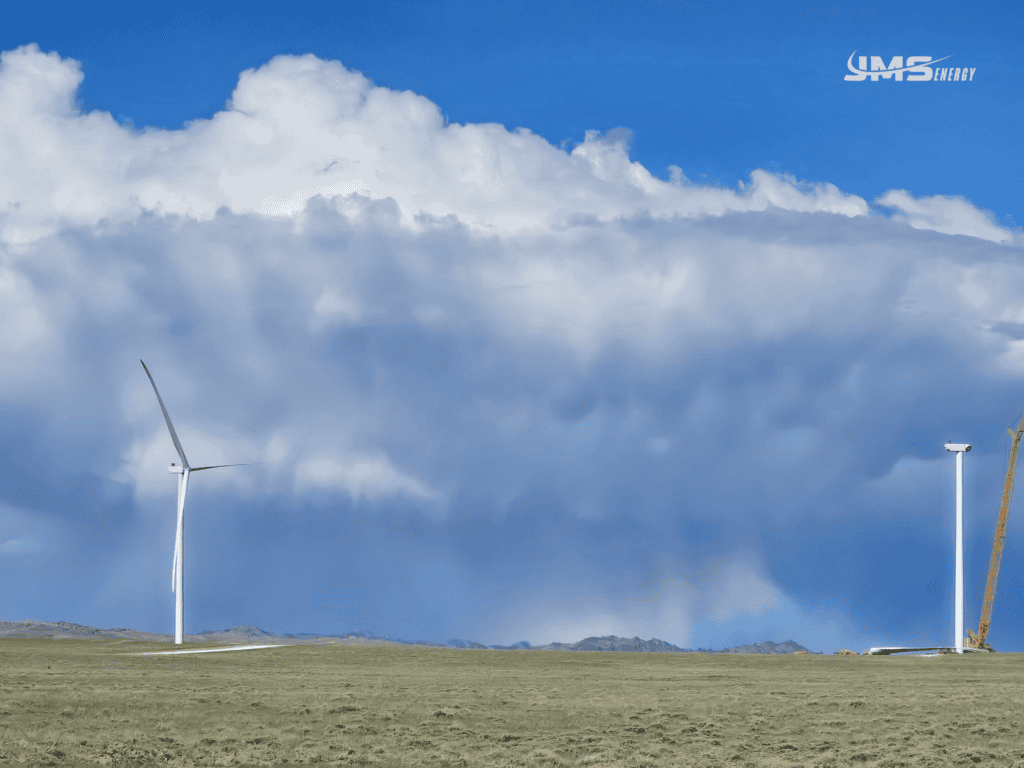

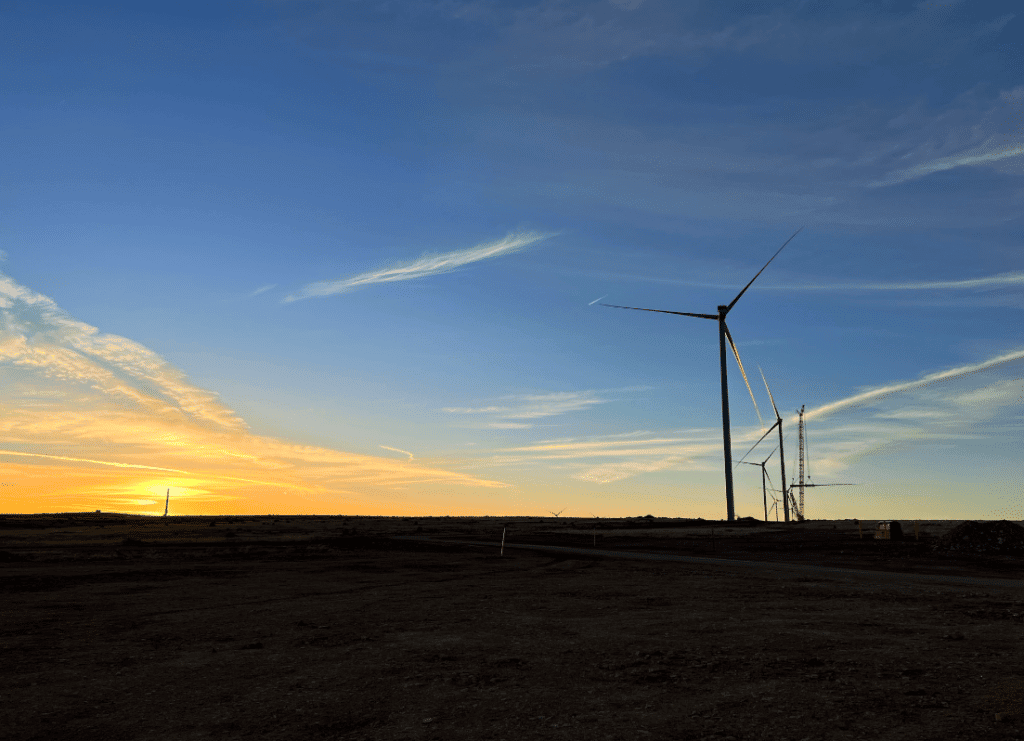

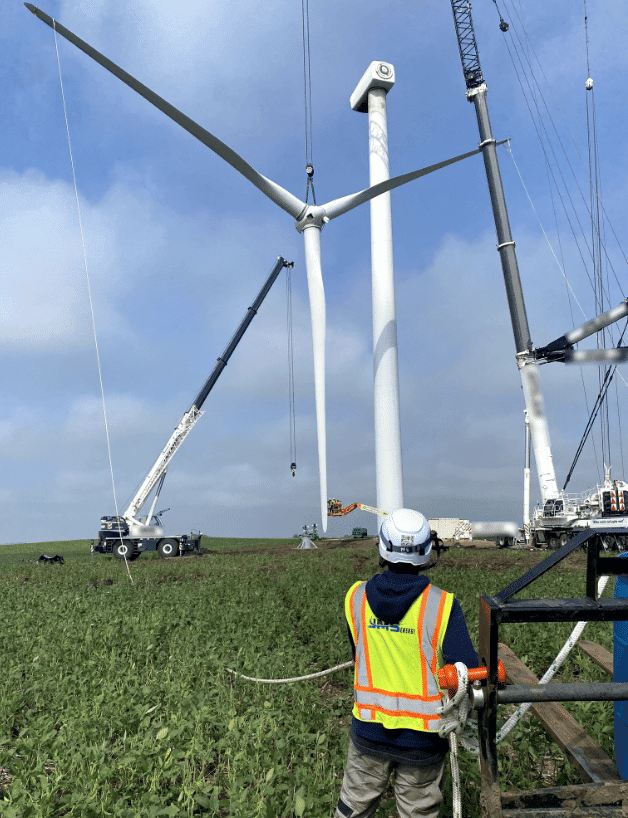

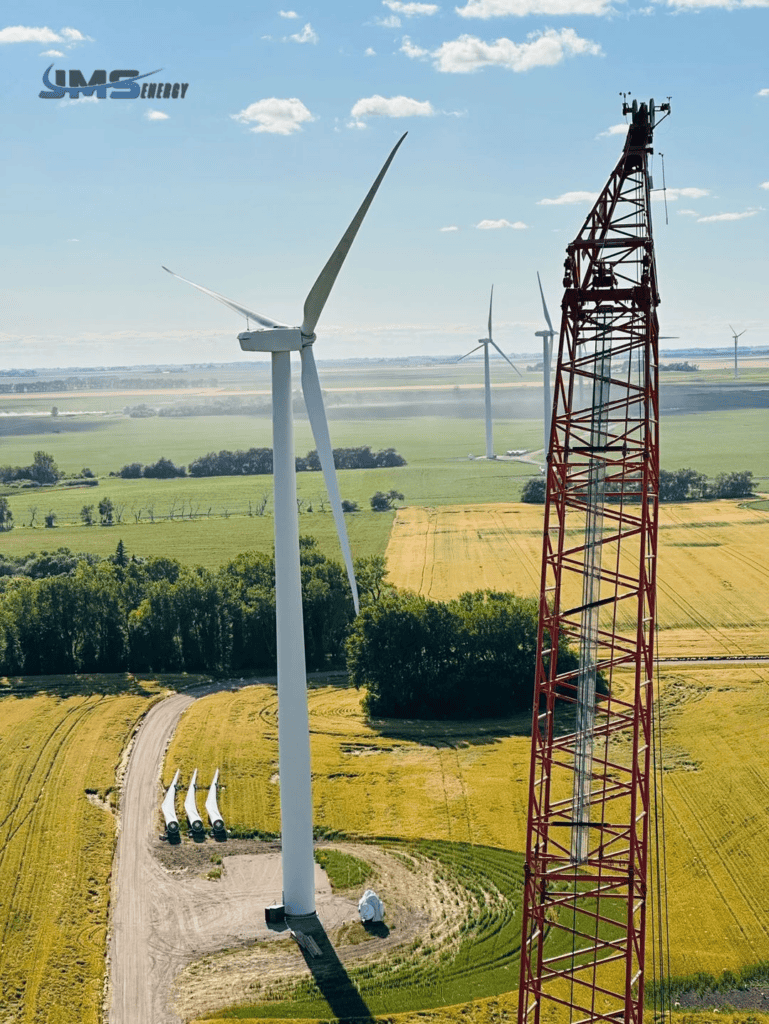

Wind Energy Services: Engineering Success for Clean Energy

JMS Energy has built a reputation as a top renewable energy EPC company by delivering comprehensive wind energy services. From geotechnical and civil design to tower wiring and repowering, their capabilities in wind energy are vast and varied. JMS Energy not only constructs new wind farms but also specializes in repowering, a process that updates older turbines to improve efficiency and output.

Wind Energy Capabilities Include:

- Full scope of design, including geotechnical, civil, electrical, and structural

- Mechanical completion and tower wiring

- Foundation construction and underground collection systems

- Operations and maintenance (O&M) building construction

- Repowering services to enhance existing turbine performance

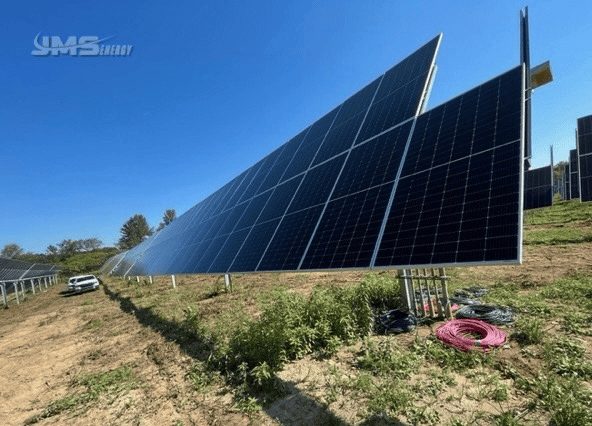

Solar Energy Projects: Harnessing the Power of the Sun

As a leading renewable energy EPC company, JMS Energy delivers expertise in solar energy project development, covering every phase from civil work and PV array installation to SCADA (Supervisory Control and Data Acquisition) integration. Their team works closely with clients to build systems that maximize solar potential while minimizing environmental impact, delivering reliable and sustainable energy solutions for communities across the country.

Solar Energy Capabilities Include:

- Civil, road, and earthwork construction

- Installation of PV (Photovoltaic) arrays and array wiring

- Medium voltage (MV) collection systems and commissioning

- Foundation construction and basin installation

Battery Storage Solutions: Supporting Grid Stability

Battery Energy Storage Systems (BESS) are integral to maintaining a balanced energy grid, particularly as renewable energy sources become more widespread. JMS Energy, as a top renewable energy EPC company, specializes in the design, installation, and maintenance of BESS solutions. These systems allow for reliable energy storage, helping clients optimize their renewable energy usage while maintaining grid stability.

Battery Storage Capabilities Include:

- Battery enclosure, Power Conversion System (PCS), and inverter construction

- Electrical and civil infrastructure design

- Commissioning and integration with existing power infrastructure

- Routine testing and maintenance to ensure operational efficiency

Fiber Optic and Communications Services for Renewable Energy Projects

Reliable communication networks are critical for managing renewable energy assets, and JMS Energy’s fiber optic services ensure these networks remain robust and secure. Their dedicated communications team handles everything from fiber optic installation to diagnostics and repair, ensuring seamless integration with energy systems. Additionally, JMS Energy’s Emergency Response Team provides rapid deployment for urgent repair needs, with the ability to respond anywhere in the contiguous United States within 12 hours.

Fiber Optic Services Include:

- Fiber cable placement (pulling and blowing)

- Inline fusion splicing and power meter testing

- OTDR (Optical Time-Domain Reflectometer) testing and visual inspections

- Diagnostic and repair services for high-reliability communications

The JMS Energy Approach to Project Management

JMS Energy’s approach to project management is centered on safety, efficiency, and transparent communication. As a renewable energy EPC company, they use their extensive industry knowledge to streamline processes, minimize costs, and ensure timely delivery of each project. With a culture that prioritizes teamwork and accountability, JMS Energy keeps all stakeholders informed and involved at every stage.

The Importance of Safety in Renewable Energy EPC Projects

For JMS Energy, safety is more than just a requirement; it is a core component of their operational culture. Their commitment to rigorous safety standards has resulted in a stellar safety record, with a TRIR of 0.00 over recent years. Every member of the JMS Energy team participates in continuous safety training, promoting a culture where safety is paramount across all job sites.

Environmental Commitment: Building a Sustainable Future

Environmental stewardship is fundamental to JMS Energy’s role as a renewable energy EPC company. They are committed to following industry best practices in environmental compliance, ensuring that their projects have minimal impact on surrounding ecosystems. From SWPPP (Storm Water Pollution Prevention Plans) and SPCC (Spill Prevention, Control, and Countermeasure) compliance to using eco-friendly construction techniques, JMS Energy takes proactive steps to protect natural resources.

Why Choose JMS Energy as Your Renewable Energy EPC Company?

Choosing JMS Energy as your renewable energy EPC company means partnering with a team that brings a wealth of experience, dedication to safety, and an innovative approach to every project. Their capabilities in wind, solar, battery storage, and communications enable them to offer tailored solutions that align with the unique needs of each client.

Benefits of Working with JMS Energy:

- Proven Expertise: With over 230 completed projects and a presence in 32 states, JMS Energy has the knowledge and skills to tackle the most complex renewable energy projects.

- End-to-End Solutions: From design to commissioning, JMS Energy’s full-service model provides streamlined processes and efficient project management.

- Commitment to Excellence: JMS Energy’s dedication to safety, quality, and sustainability is unmatched, making them a top choice for reliable and resilient renewable energy solutions.

About JMS Energy

JMS Energy has over 30 years of experience in the renewable energy sector, positioning itself as a trusted leader in the industry. Specializing as a renewable energy EPC company, JMS Energy offers comprehensive services across wind, solar, battery storage, and fiber optics, providing high-quality, cost-effective energy solutions to clients nationwide. Their dedication to safety, quality, and customer satisfaction has made them a preferred partner for businesses and communities committed to sustainable energy. With a mission to lead the renewable energy revolution, JMS Energy continues to deliver innovative solutions, powering a cleaner and greener future across America.

For more information on JMS Energy’s services and to see how they can support your next renewable energy project, visit jmsenergy.net to learn more about their expertise and commitment to sustainable energy.