Onshore vs offshore wind, which is offering sustainable solutions to power needs worldwide. In this context, understanding the differences and advantages between onshore and offshore wind energy is crucial. Moreover, knowing how to harness these energies to their fullest potential requires expert services. JMS Energy stands out as a leader in providing cutting-edge wind services. Through this FAQ, we will explore the critical aspects of onshore vs. offshore wind energy and discover why JMS Energy is the best choice for your wind power solutions.

Table of Contents

Onshore VS Offshore Wind #1. What is the difference between onshore and offshore wind energy, and how does it affect the choice of services provided by JMS Energy?

Onshore wind energy refers to wind turbines installed on land, capturing wind that moves across fields and hillsides. Offshore wind energy, on the other hand, involves turbines placed in bodies of water, usually oceans, where wind speeds are typically higher and more consistent than on land.

The choice between onshore and offshore depends on a variety of factors, including cost, efficiency, and environmental impact. Onshore wind projects generally have lower installation and maintenance costs due to easier access and less complex logistics. However, offshore wind farms can generate more power thanks to stronger and steadier winds at sea.

JMS Energy provides comprehensive services tailored to both onshore and offshore projects. Their expertise spans site assessment, installation, maintenance, and optimization, ensuring that each project is executed with maximum efficiency and minimal environmental impact. By leveraging their extensive industry experience, JMS Energy can guide clients in making the best decision based on geographical and economic considerations.

Onshore VS Offshore Wind #2. What are the economic implications of choosing onshore over offshore wind energy for long-term investments, and how does JMS Energy support clients in maximizing their return on investment?

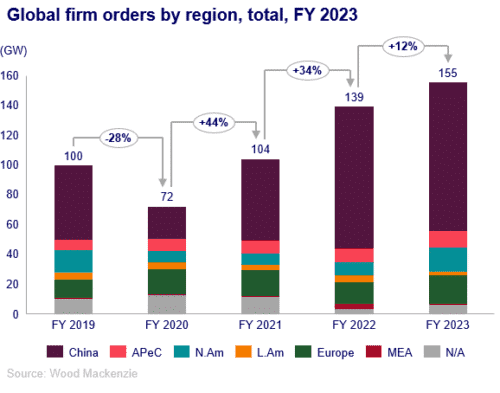

Economically, onshore wind projects typically require less initial capital investment compared to offshore projects due to simpler installation processes and lower material and labor costs. However, offshore projects, despite higher upfront costs, often offer higher energy yields and potential long-term returns due to better wind resources.

JMS Energy supports clients in maximizing their return on investment through detailed feasibility studies and financial modeling. They assess site-specific wind data, energy output forecasts, and lifecycle costs, providing clients a clear understanding of potential financial outcomes. JMS’s skilled project managers and engineers work closely with clients to develop cost-effective strategies that meet specific investment goals, whether it involves onshore’s practical, immediate savings or offshore’s promising, long-term gains.

Onshore VS Offshore Wind #3. How does the environmental impact differ between onshore and offshore wind farms, and how does JMS Energy address these concerns in their services?

The environmental impact of wind farms is a critical consideration. Onshore wind farms may impact local wildlife habitats and landscapes, while offshore wind farms could affect marine ecosystems and bird migration patterns. Thus, mitigating these impacts is vital for sustainable development.

JMS Energy is committed to minimizing the environmental footprint of wind projects. Their services include conducting thorough environmental impact assessments and devising strategies to mitigate negative effects. This could involve selecting turbine locations that avoid sensitive wildlife zones, employing technology to reduce noise pollution, and monitoring ecological impacts post-installation. JMS’s focus on sustainability and environmental preservation ensures that their projects not only meet energy needs but also contribute positively to the natural surroundings.

Onshore VS Offshore Wind #4. Considering technical challenges, how does JMS Energy ensure the reliability and efficiency of onshore and offshore wind turbines?

Technical reliability and efficiency are paramount in wind energy projects, where technological failure can lead to significant downtime and financial loss. Offshore wind farms face additional challenges like harsh weather conditions and corrosion due to saltwater.

JMS Energy addresses these challenges with a comprehensive suite of technical services. These include predictive maintenance strategies using cutting-edge technology to monitor turbine performance in real time, allowing for rapid identification and rectification of potential issues. JMS Energy also employs corrosion-resistant materials and specialized coatings for offshore turbines, greatly enhancing durability and lifespan.

Moreover, JMS’s team of skilled engineers conducts regular performance audits and optimization checks, ensuring turbines operate at peak efficiency. Their commitment to innovative technological solutions and meticulous maintenance programs underpins the high reliability and performance of both onshore and offshore installations.

Onshore VS Offshore Wind #5. What role does community engagement play in developing onshore and offshore wind projects, and how does JMS Energy facilitate this interaction?

Community engagement is crucial for the success of wind energy projects, as it fosters public support and addresses potential concerns. Onshore projects especially require harmonious integration with local communities due to their proximity to inhabited areas.

JMS Energy recognizes the importance of transparent communication and actively engages with stakeholders throughout the project lifecycle. They conduct community outreach programs to educate locals about the benefits and operational aspects of wind energy. JMS also establishes open channels for feedback, addressing queries and concerns promptly and thoughtfully.

For offshore projects, JMS facilitates dialogues with maritime stakeholders, ensuring navigational and fishing activities are considered during the planning and implementation phases. By fostering strong relationships and mutual understanding with communities and stakeholders, JMS Energy guarantees smoother project implementation and enduring positive impacts at the local level.

Conclusion

As the wind energy sector continues to evolve, the interplay between onshore and offshore solutions becomes increasingly nuanced. Whether opting for the accessible, cost-effective path of onshore wind farms or the robust, potential-rich journey in offshore waters, choosing the right partner is crucial. JMS Energy’s comprehensive expertise and dedication to innovation and sustainability make them the premier choice for navigating the complexities of wind energy. Their client-centered approach ensures that every project not only meets energy goals but also enriches local communities and protects natural environments for future generations.