Table of Contents

In the renewable energy industry, the longevity and efficiency of equipment are critical to maintaining high productivity and minimizing operational costs. One essential process in this realm is Major Component Exchange (MCE), a practice that has gained prominence due to the growing need for sustainable maintenance and optimization of wind turbines and other large-scale renewable energy systems. JMS Energy, a leader in renewable energy services, specializes in providing these crucial services to maintain operational integrity and enhance the performance of energy assets. In this article, we will explore the concept of Major Component Exchange, its significance, and how it contributes to the efficiency of renewable energy operations.

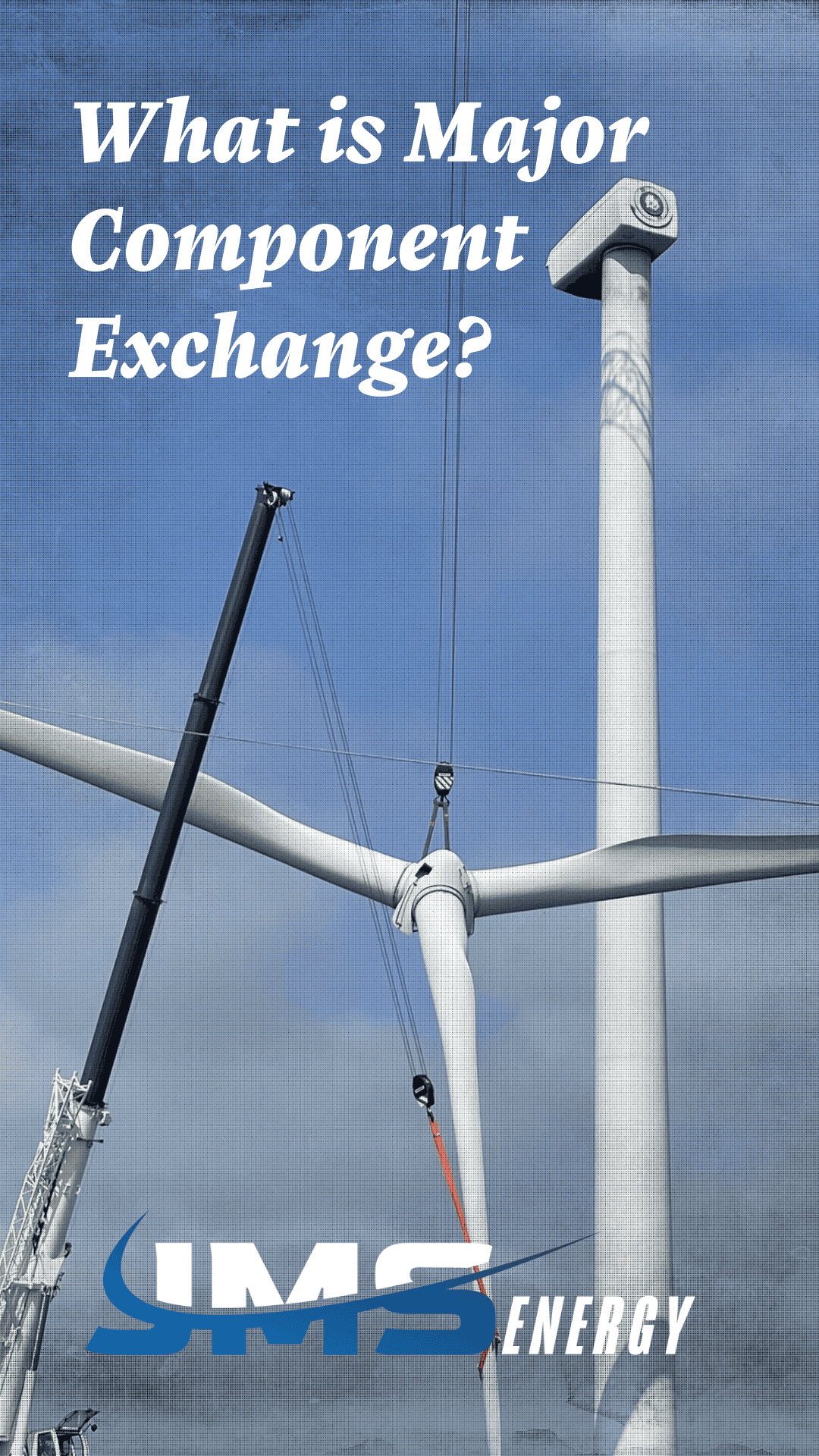

What is Major Component Exchange (MCE)?

Major Component Exchange refers to the replacement of large, critical parts in renewable energy systems, primarily in wind turbines. These components include but are not limited to:

- Gearboxes

- Generators

- Blades

- Main bearings

- Transformers

The exchange of these parts becomes necessary when a component reaches the end of its operational life or experiences a failure that could severely impact the performance of the system. Unlike smaller parts, major components are complex and costly to repair or replace, and their failure often results in significant downtime. By carrying out a Major Component Exchange, energy companies can quickly replace faulty parts and minimize operational interruptions, thus ensuring continuous energy production.

Why is Major Component Exchange Important?

Wind turbines and other renewable energy systems are subject to constant wear and tear due to their exposure to natural elements like wind, rain, and extreme temperatures. Over time, critical components deteriorate, leading to inefficiencies or outright failures. Major Component Exchange is essential because:

- Minimized Downtime: The process allows for quick replacement of faulty parts, reducing the time the system is offline. Minimizing downtime is particularly important in the renewable energy industry, where delays in energy production can lead to significant financial losses.

- Prolonged Asset Life: Regularly replacing major components extends the overall life of the system. This means that companies can maximize their return on investment by keeping the turbines or systems operational for longer periods before requiring complete overhauls.

- Cost-Effectiveness: Replacing individual components is often more cost-effective than replacing entire systems. With an MCE, you can avoid the expenses of procuring new turbines or energy systems while still ensuring optimal performance.

- Enhanced Performance: Exchanging old or worn-out components with new, more efficient ones can improve the overall output of a renewable energy system, allowing it to generate more energy at lower costs.

- Predictive Maintenance: MCE allows companies to plan for maintenance rather than react to sudden failures. This proactive approach helps avoid emergency situations, which can be more expensive to handle and could result in longer downtimes.

The Process of Major Component Exchange

Conducting a Major Component Exchange involves several steps that require careful planning, coordination, and specialized expertise. The process typically follows these phases:

1. Condition Monitoring

Before performing an MCE, energy companies use condition monitoring systems (CMS) to assess the health of critical components. This monitoring includes analyzing vibration data, temperature variations, and operational stresses on the turbine or system. If CMS indicates that a major component is nearing the end of its life, it triggers the planning of a component exchange.

2. Logistics and Planning

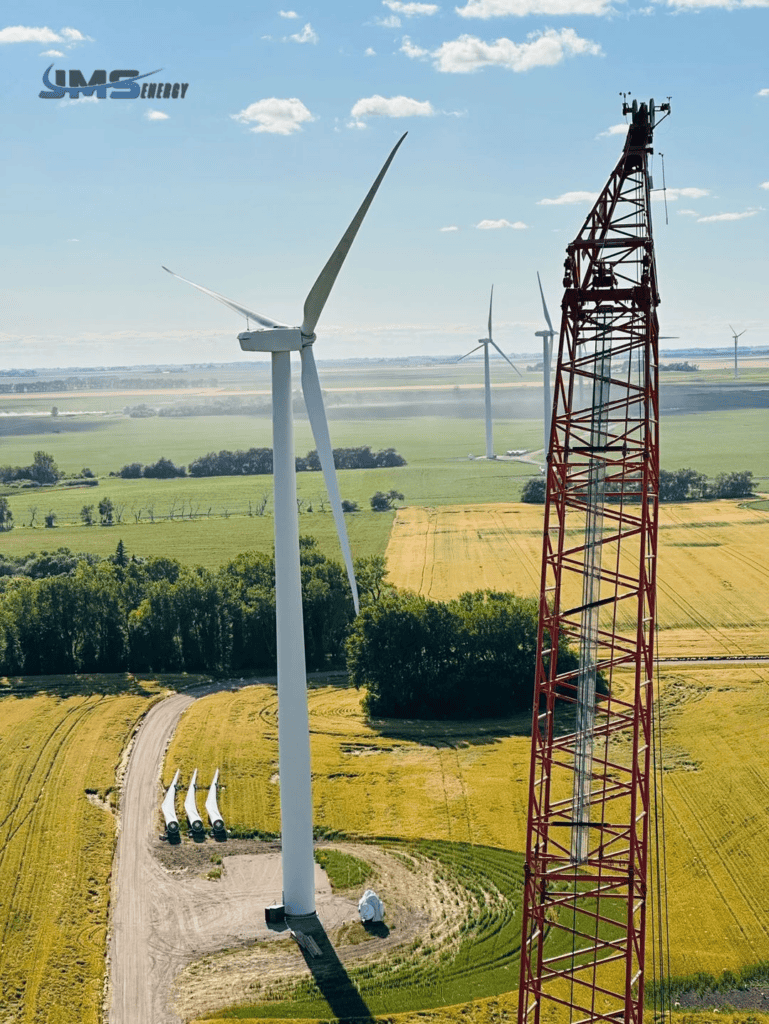

Since major components are typically large and heavy, planning for their transportation and storage is crucial. For instance, wind turbine blades and gearboxes may require specialized cranes and heavy-duty vehicles for transport and installation. JMS Energy, with its expertise in wind farm construction and maintenance, ensures that logistics are handled efficiently to avoid delays.

3. Replacement

Once the faulty component is identified and the logistics are in place, the actual exchange begins. This involves dismantling the faulty part and installing a new or refurbished component. The process may take several hours or even days, depending on the size of the component and the complexity of the exchange. JMS Energy’s experienced technicians use specialized tools and equipment to ensure that the replacement is done safely and efficiently.

4. Testing and Commissioning

After the new component is installed, it must undergo rigorous testing to ensure it functions correctly. This phase is critical to avoid potential malfunctions that could arise due to incorrect installation. JMS Energy employs thorough testing procedures to confirm that the system is running at optimal performance levels after the exchange.

5. Post-Exchange Monitoring

Even after a successful exchange, the newly installed component is closely monitored to ensure it integrates well with the rest of the system. Any irregularities in performance can be immediately addressed to prevent further issues.

Benefits of Working with JMS Energy for Major Component Exchange

JMS Energy is a trusted partner in the renewable energy industry, known for its expertise in providing turnkey solutions, including Major Component Exchange services. Here are some benefits of working with JMS Energy:

- Comprehensive Expertise: With years of experience in renewable energy construction and maintenance, JMS Energy has the technical know-how to handle complex MCE projects with precision and care.

- Safety First: Safety is paramount in MCE operations. JMS Energy adheres to stringent safety protocols, ensuring that all exchanges are performed without compromising the safety of workers or equipment.

- State-of-the-Art Equipment: JMS Energy utilizes the latest tools and technology, including specialized cranes, monitoring systems, and precision equipment to perform Major Component Exchanges efficiently and effectively.

- Custom Solutions: Every renewable energy system is different. JMS Energy offers customized MCE solutions tailored to the specific needs of each project, whether it’s for a wind farm or another renewable energy system.

- Reduced Downtime: JMS Energy’s efficient processes and expert planning help reduce the time it takes to complete an MCE, minimizing the disruption to energy production.

Conclusion

Major Component Exchange is a vital process in the maintenance and optimization of renewable energy systems, particularly wind turbines. By regularly replacing critical components like gearboxes, generators, and blades, energy companies can extend the life of their assets, enhance performance, and reduce downtime. JMS Energy specializes in providing these services, ensuring that renewable energy systems remain efficient and productive throughout their operational life.

For more information on Major Component Exchange or to inquire about JMS Energy’s services, visit jmsenergy.net. JMS Energy offers a full range of renewable energy solutions, ensuring that your energy systems remain at peak performance year-round.